3D.aero - Where Quality Meets Innovation.

Empowering Precision, Elevating Automation.

Erfahre mehrInspektionssysteme für die Produktion und Instandhaltung von morgen

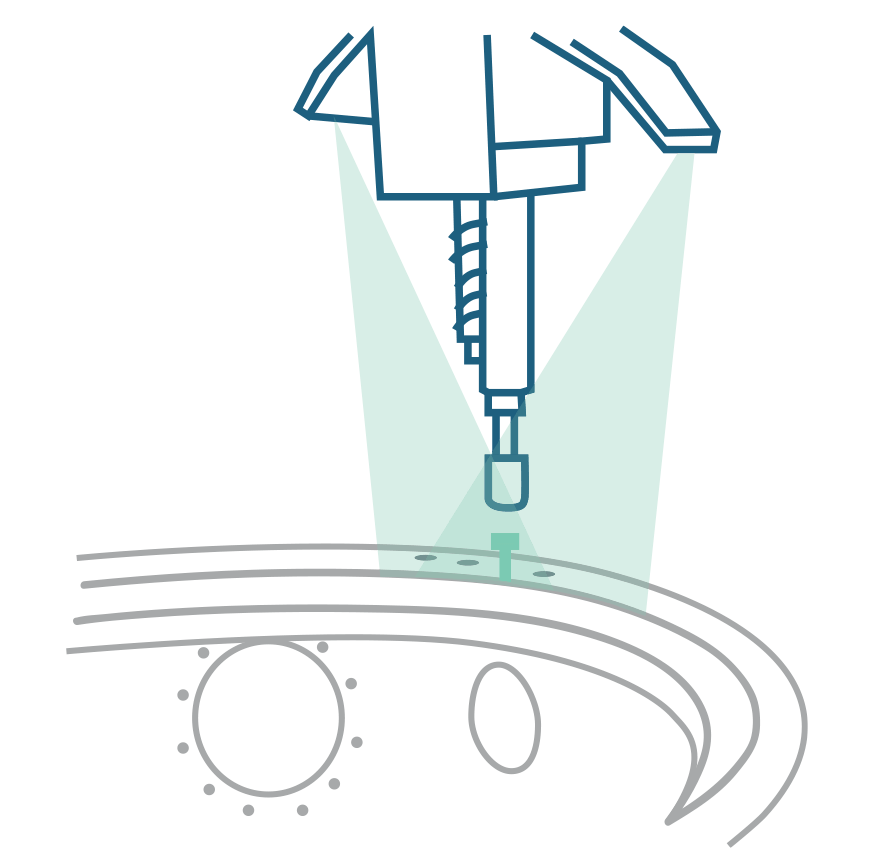

Unsere Lösungen ermöglichen eine Qualitätssicherung mit hoher Zuverlässigkeit, Genauigkeit und Autonomie, wie beispielsweise hochgenaue Oberflächeninspektion, 3D Bauteilvermessung und -identifikation oder Überwachung des Montagefortschritts.

Sie haben eine eigene Applikation im Kopf? Dann fordern Sie uns heraus und profitieren Sie von unserem Know-how im Bereich industrieller Messtechnik und Automatisierung!

360° Qualität

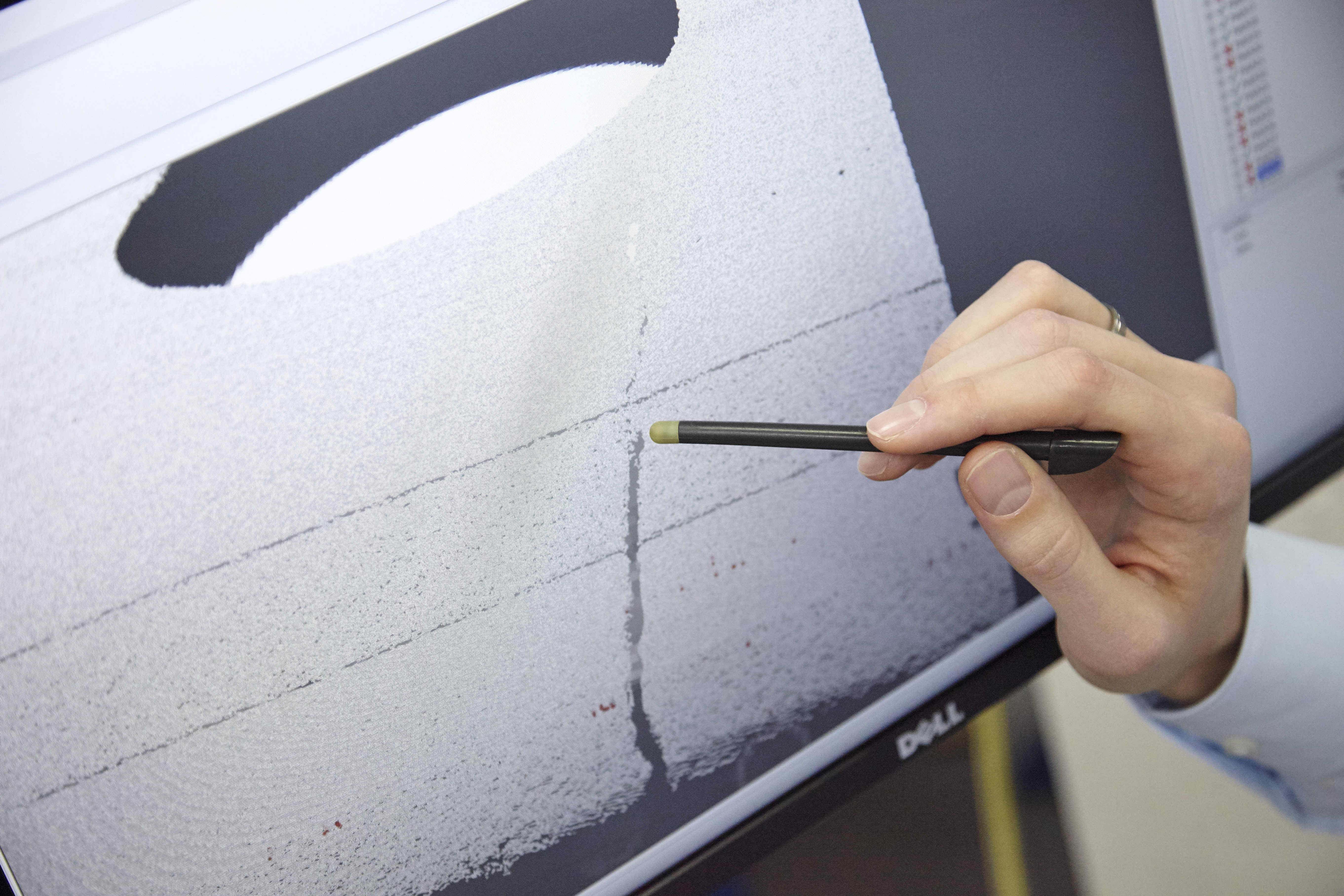

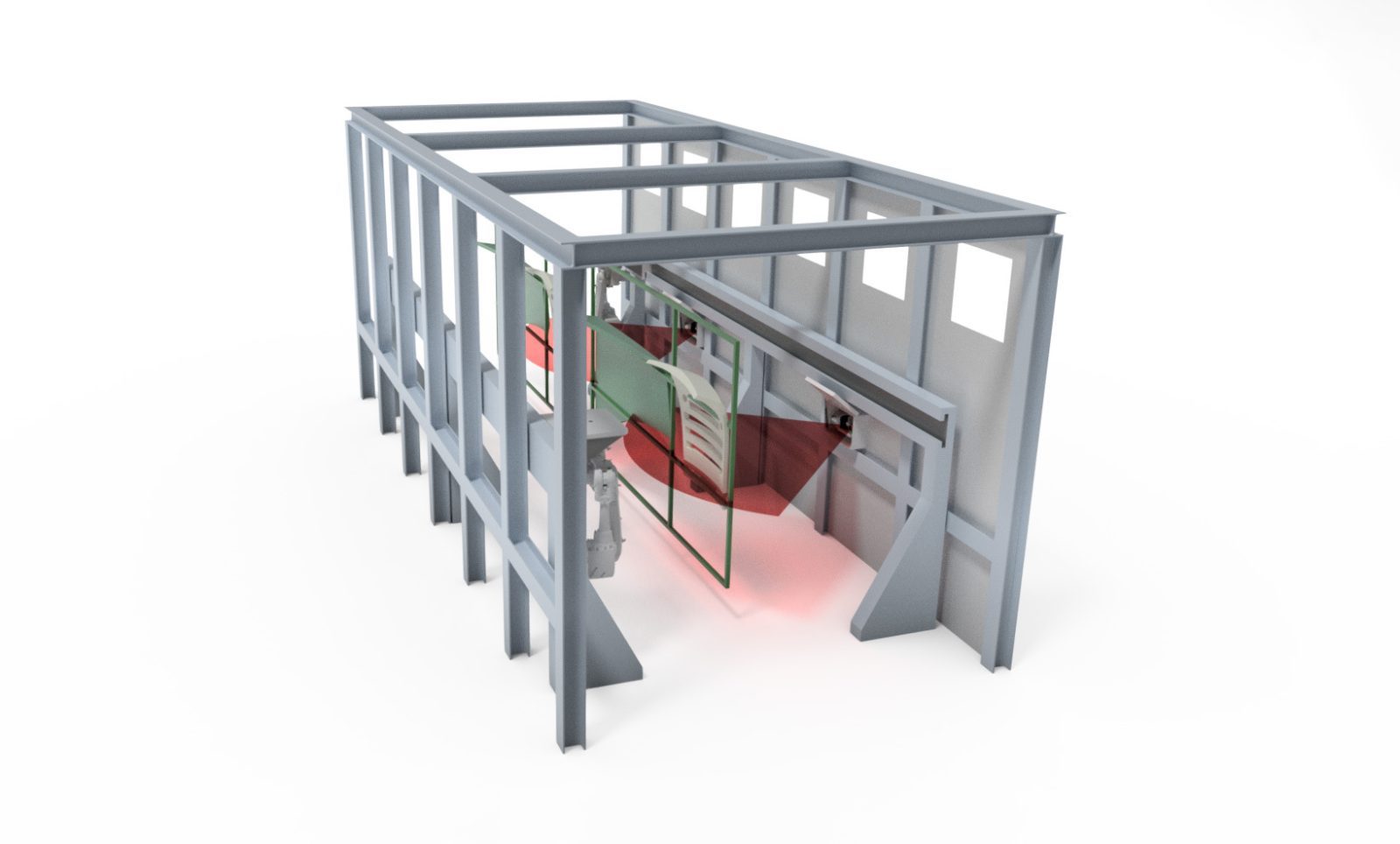

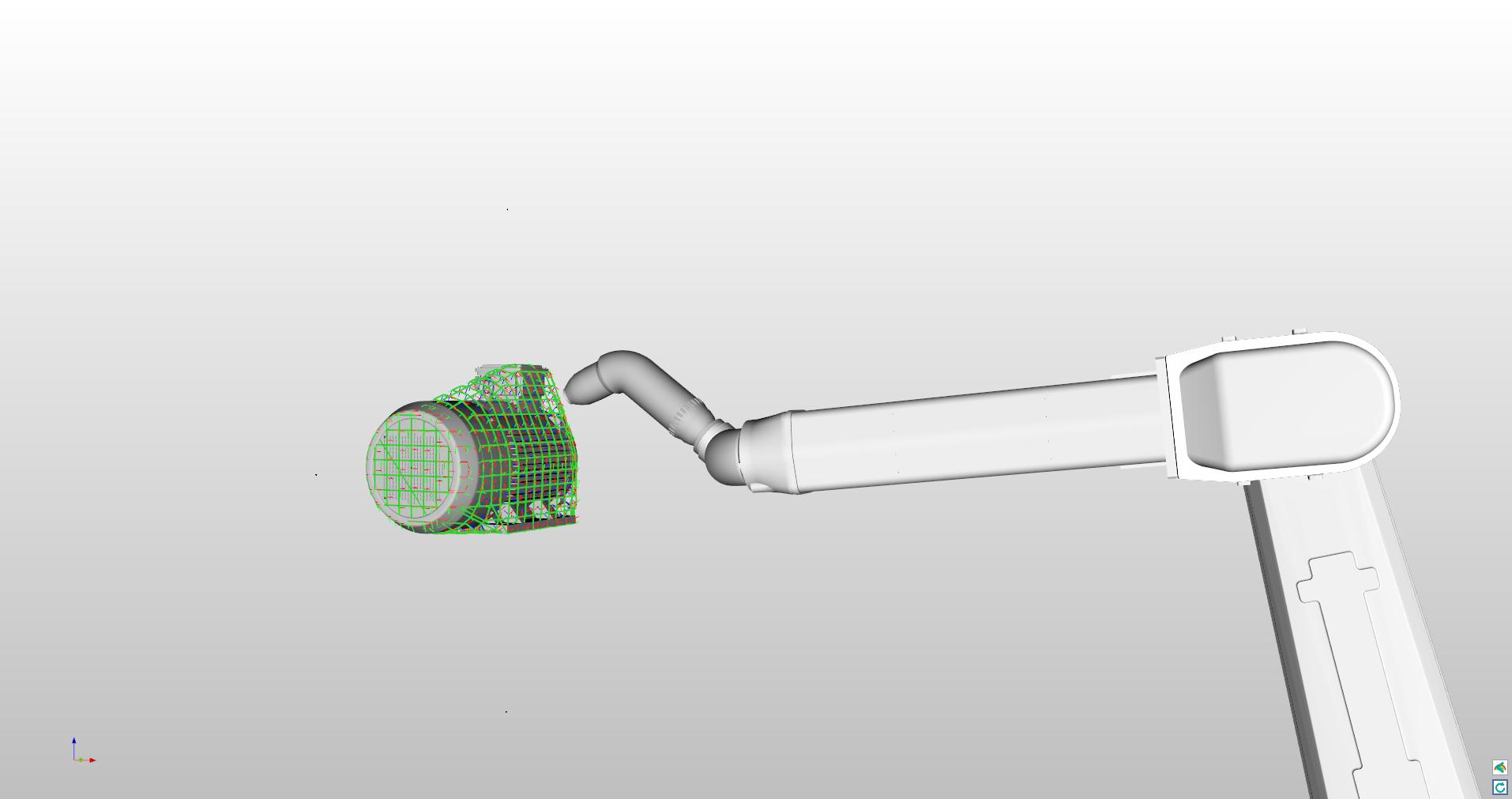

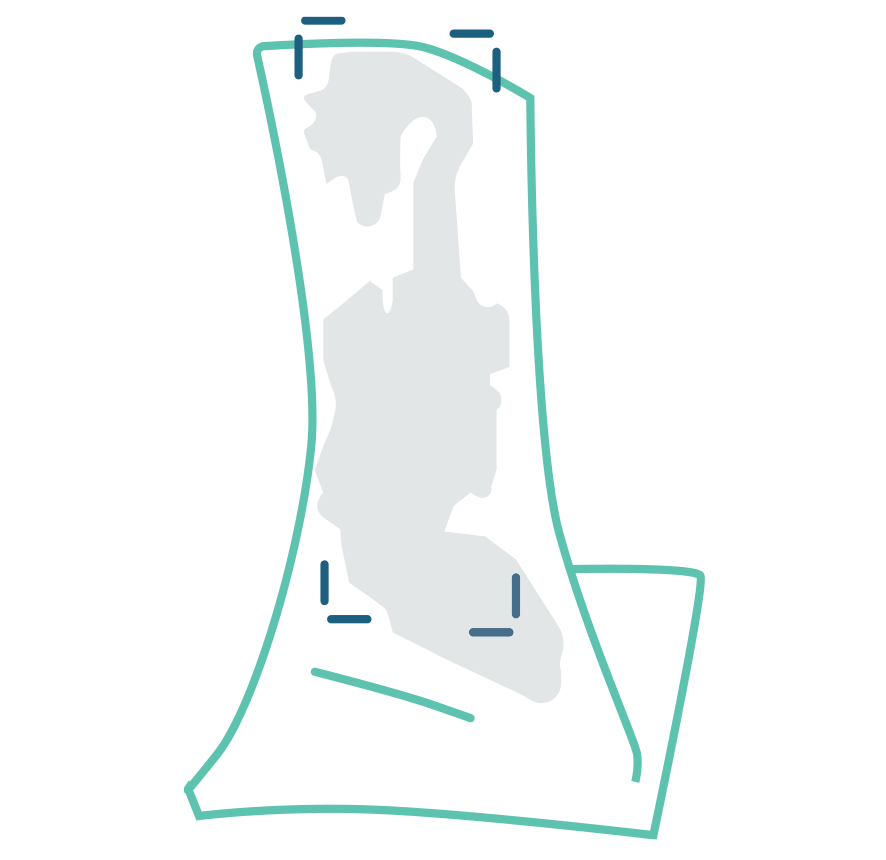

Wir unterstützen Sie auf dem Weg in die automatisierte Inspektion und die autonome Produktion der Zukunft. Von 3D Oberflächeninspektionen im Mikrometer-Bereich über KI-unterstützte und mobile Inspektionsprozesse bis hin zu großflächiger Bauteilvermessung deckt unser Portfolio ein breites Spektrum messtechnischer Anwendungen ab. Vergleichbar mit der Transformation vom realen Bauteil über die Punktewolke hin zum farbigen PXL+ ™ Datensatz, betreuen wir Sie im Prozess von der Ideenfindung über die Entwicklung bis zur Lieferung der schlüsselfertigen Anlage. Unser größtes Ziel ist Ihre Zufriedenheit!

Erfahre mehrUnsere Expertise

-

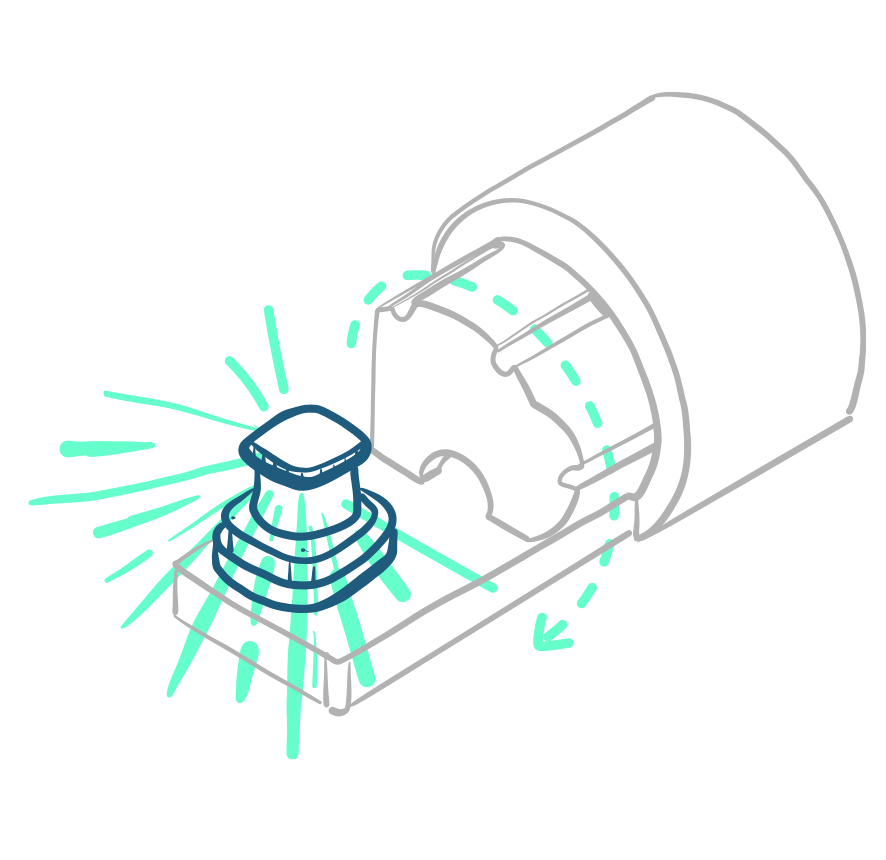

Sensorik

Umfassendes Know-how in industrieller 2D und 3D Messtechnik unabhängig von Herstellern

-

Algorithmik

Wir kombinieren klassische Bildverarbeitung mit künstlicher Intelligenz zum autonomen System

-

Automatisierungssoftware

Hauseigene Software „3D.OS“ zur Automatisierung, Inspektion, Detektion und Klassifikation

-

Systemintegration

Von der Konstruktion, über die Fertigung bis zum CE-Zertifikat alles aus einer Hand

-

Forschungsnähe

Wissenschafts- und anwendungsorientierte Forschung mit industriellem Technologietransfer

Unsere 3D.Vorgehensweise

Interesse geweckt? Ich bin gerne für Sie da!

“Lernen Sie unsere praxisnahe und lösungsorientierte Arbeitsweise kennen, die mit der unkomplizierten Erprobung neuer Ideen im kleinen Rahmen beginnt und zur Umsetzung einer zertifizierten Automatisierungslösung führt.“

– Michael Ernst, Vertriebsleitung

Ich freue mich auf den Austausch!